摘要:,,本文研究了电子设备中次铁磁性的优化。通过深入研究次铁磁性的特性和影响因素,提出了一系列优化措施,以提高电子设备的性能和稳定性。这些优化措施包括改进材料选择、设计更高效的磁路结构以及优化制造工艺等。通过实施这些策略,可以显著提高电子设备的运行效率和可靠性,为电子设备行业的进一步发展奠定基础。

In the realm of electronic device technology, the concept of sub-iron magnetism has gained significant importance due to its potential in enhancing device performance. Sub-iron magnetism refers to the magnetic properties exhibited by materials at intermediate states between their fully magnetic and non-magnetic phases. This article will explore the methods to achieve and optimize sub-iron magnetism in electronic devices, aiming for improved performance and efficiency.

1、Understanding Sub-Iron Magnetism

Sub-iron magnetism arises when certain materials are subjected to conditions that allow them to exhibit magnetic properties without reaching their full magnetic saturation. This intermediate state offers unique advantages in terms of device sensitivity, response time, and power consumption. Understanding the underlying mechanisms of sub-iron magnetism is crucial for effective implementation and optimization.

2、Material Selection

The first step in achieving sub-iron magnetism in electronic devices is selecting the right materials. Materials that exhibit sub-iron magnetism must possess suitable magnetic properties at intermediate states. Additionally, they should be compatible with the other components in the device and capable of withstanding the operating conditions without significant degradation.

3、Device Design and Integration

The design of electronic devices plays a crucial role in achieving and optimizing sub-iron magnetism. The device architecture should be tailored to accommodate the selected material and its magnetic properties. Proper integration of sub-iron magnetic materials into the device structure is essential for ensuring optimal performance. This includes considering factors such as material placement, interconnections, and thermal management.

4、Processing Techniques

Processing techniques used during manufacturing have a significant impact on sub-iron magnetism in electronic devices. Techniques such as heat treatment, doping, and surface modification can be used to tailor the magnetic properties of materials. These techniques allow fine-tuning of the material's response to external magnetic fields, thereby optimizing sub-iron magnetism in the device.

5、Experimental Characterization and Analysis

Experimental characterization and analysis are essential for optimizing sub-iron magnetism in electronic devices. This involves measuring the magnetic properties of the material under various conditions and correlating these properties with device performance. Advanced testing techniques such as magnetic field scanning, magnetic spectroscopy, and magnetic imaging are used to obtain detailed insights into sub-iron magnetism. These insights provide valuable information for further optimizing device design and material properties.

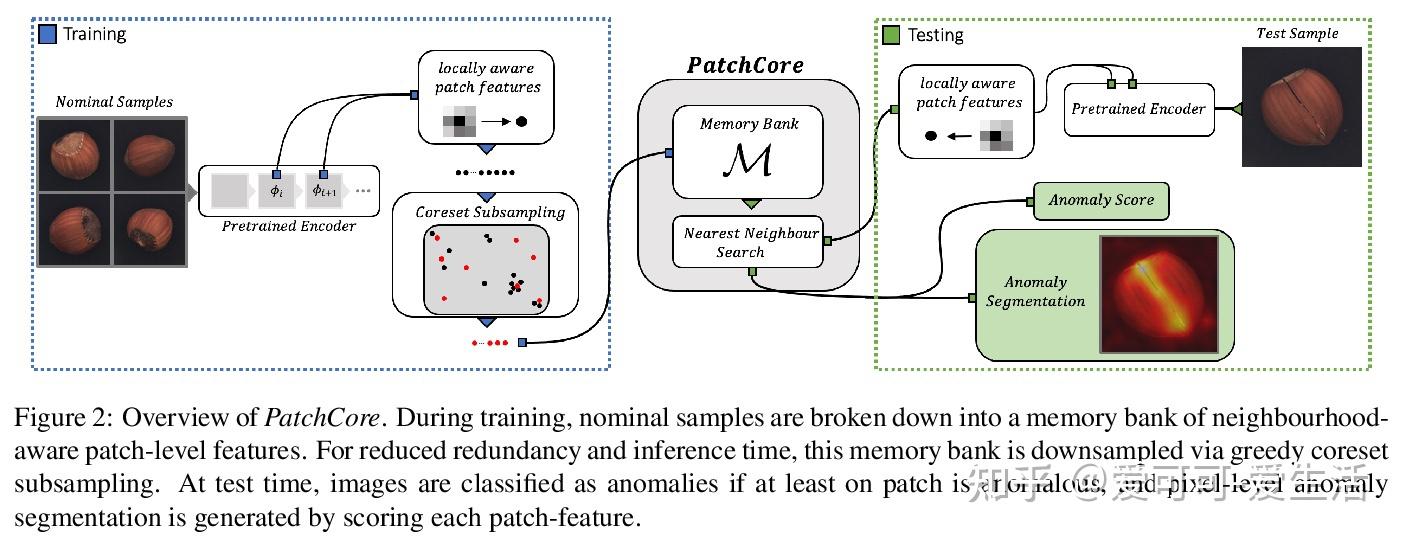

6、Software Simulation and Modeling

Software simulation and modeling play a pivotal role in optimizing sub-iron magnetism in electronic devices. These tools allow for virtual testing and analysis of device performance under different conditions. By simulating the behavior of sub-iron magnetic materials, engineers can predict device performance and identify areas for improvement. This approach significantly reduces the time and cost associated with experimental testing, enabling faster optimization of sub-iron magnetism in electronic devices.

In conclusion, achieving and optimizing sub-iron magnetism in electronic devices requires a multi-disciplinary approach that involves material science, device engineering, and software simulation. Through a combination of material selection, device design, processing techniques, experimental characterization, and software modeling, engineers can achieve significant improvements in device performance and efficiency. The ongoing research in this field promises to bring further advancements in electronic device technology, driven by the unique properties of sub-iron magnetism.

京公网安备11000000000001号

京公网安备11000000000001号 京ICP备11000001号

京ICP备11000001号